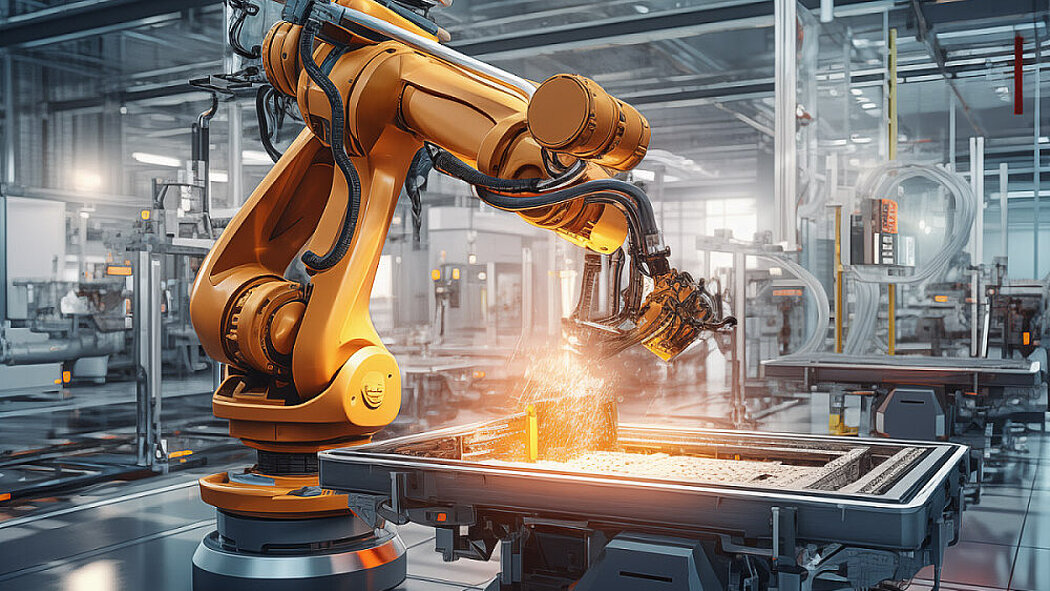

Perfectly positioned for servo motors

According to recent studies by renowned market research institutes, the market for servo motors and servo drives will grow by almost 6% annually to around USD 20.5 billion by 2029. In addition to the automotive industry, the main drivers are increasing automation and the use of robotics in industry. In addition, pneumatic and hydraulic systems are increasingly being replaced by electromechanical solutions. 30 to 40 percent of the servo drives used are equipped with a brake.

"In this globally growing market, KENDRION is perfectly positioned both technologically and geographically," explains Waldemar Schaermann, Product Manager at KENDRION. “With locations in Europe, the USA, India and China, we are present wherever our brake technology is in demand. In addition, with our broad product portfolio, consisting of basic series of permanent magnet and spring-applied brakes and more than 2,000 active customer-specific brakes, we can always provide our industrial customers with an optimum brake solution, depending on the application.”

Powerful Application-Teams at the two German sites in Villingen and Aerzen advise on the best individual solution. "We not only offer our customers products, but also specific solutions that we develop together," says Waldemar Schaermann, describing the process. "We realize the customer-specific product properties in short development periods and guarantee that only products of the highest quality leave our factories through comprehensive and application-related tests in our in-house laboratory as well as through tests during production."

High power-density and precision

Servomotors are characterized by high power density, dynamics and precision - properties that the brake must also support. "The high motor power and the requirement for 24/7 operation result in high operating temperatures," explains Waldemar Schaermann. “Brakes that are installed directly in the servomotor housing must be able to withstand these temperatures reliably over the entire service life of the application. This requires a high degree of design and the use of high-quality materials.”

The high demands on the compactness and positioning accuracy of the servomotors require brakes with the highest power density and minimal or no backlash. In addition to high precision, durability and the reliable guarantee of the required safety standards are also on the list of desired properties.

Power density vs. Flexibility

The PM brake has the highest power-density in the market and the technology of choice wherever a very high torque is required in a very small installation space. In addition, permanent magnet brakes open without residual torque, which enables wear-free and dust-free operation and are characterized by their zero backlash and corresponding precision. With the High Torque Line and the established PM Line, KENDRION offers its customers a wide range of customizable PM brakes.

Spring-applied brakes are compact, easy to install and deliver high braking energy and wear resistance. The application-specific, modifiable organic friction linings and the option of applying the brake to both the floating-bearing and fixed-bearing side of the motor ensure a high degree of flexibility. We offer spring-applied brakes with its Servo Line and the extremely slim Servo Slim Line

"Every application requires its own brake technology," summarizes Waldemar Schaermann. "We have both solutions in our portfolio and can advise our customers so that they always find the optimum brake for their application with us."