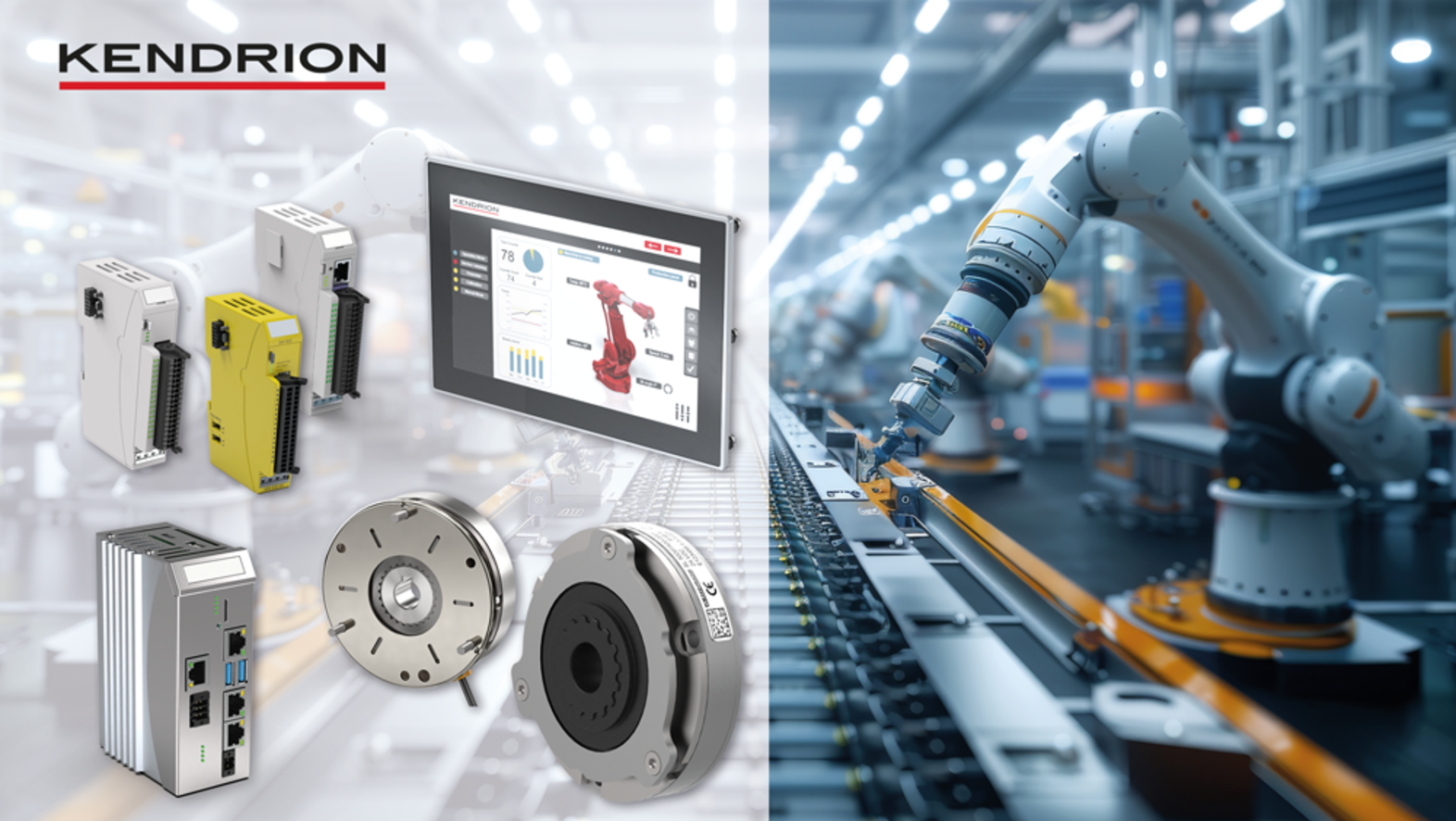

‘Safety first’ with functional safety solutions from Kendrion

Functional safety is now part of the range of functions offered by modern machines. With the certified FSoE (Fail Safe over EtherCAT) safety components FIO Safety PLC and the associated EtherCAT safety I/O modules, KENDRION relies on proven technologies: the Standard-CODESYS programming environment and the powerful EtherCAT® real-time field bus.

Integrated safety for demanding motion and robotic solutions

The control and safety program integrated in CODESYS allows for a simple and clear data exchange between the yellow and grey worlds. The modular EtherCAT-based I/O system Kuhnke FIO from KENDRION enables the integration of both safe and non-safety-relevant modules. It is therefore a practical solution for all your peripheral expansion needs, with low engineering and commissioning costs. Our safety I/Os can be connected to a higher-level control system via a bus coupler or operated directly on one of our FIO controllers. Further EtherCAT Safety (FSoE) devices can be connected and safely monitored and controlled using the FIO Safety PLC.

CODESYS Safety Control (Safety PLC)

With the TÜV certification, KENDRION also received a PLCopen safety certification for the safety control. Rounded off by this certificate, the decentralised SIL3 safety control Kuhnke FIO Safety PLC is easy to integrate anywhere in accordance with IEC 61508. Configuration and programming is done with CODESYS and transferred securely via EtherCAT/ FSoE. CODESYS provides numerous certified safety blocks, such as emergency stop, two-hand operation, muting, etc. according to PLCopen. In addition, the user can develop customised function blocks for their application if required. This means that even complex FSoE slaves, such as drives, can be controlled safely and continuously monitored.

FSoE Safety I/O – safe digital inputs and outputs for the most demanding requirements

The FIO product family offers a wide range of digital modules with safe inputs and outputs for challenging safety applications.

The inputs are ideal for connecting sensors with potential-free contacts and can be flexibly combined with integrated or external test pulse outputs. The outputs switch 24 V DC loads independently of each other, which must be reliably disconnected in the event of a fault.

All inputs and outputs meet the highest safety standards:

- Category 4, PL e according to EN ISO 13849-1

- SIL 3 according to IEC 61508/62061

Flexible integration thanks to FSoE

In addition to the FIO Safety PLC, any other safety control with FSoE (Fail Safe over EtherCAT) can be used for the safe control of the Safety I/O modules. The modules support standard-compliant FSoE, so that they are compatible with any FSoE masters.

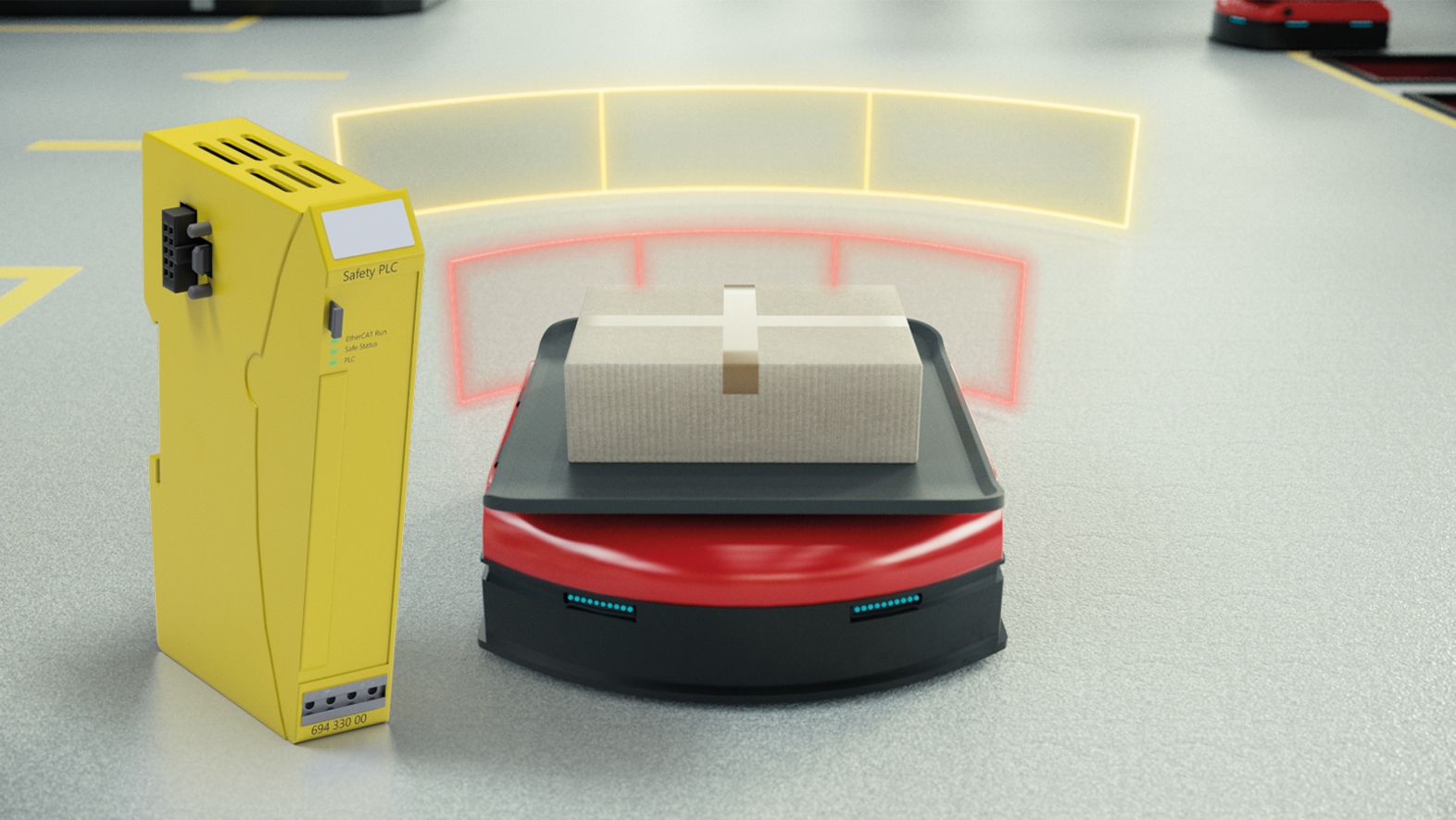

Why is the Kendrion Safety PLC particularly suitable for applications in robotics and AGVs?

Thanks to the integrated FPU, a large process image and the option of programming complex functions in C, our Safety PLC is ideal for demanding applications in the field of robotics and automated guided vehicles (AGVs).