Kendrion is your expert for safety and holding brakes

AGVs and AMRs have become a common sight in warehousing and production environments, where they perform repetitive tasks and transport goods quickly, safely, and efficiently.

To protect persons or materials in an emergency, our electromagnetic brakes safely stop the AGV or AMR: from small load units to forklifts to large transport systems and beyond, we offer braking solutions for almost any electrically driven vehicle.

Especially for industrial trucks, KENDRION INTORQ has already established itself as the market leader for spring-applied brakes in Europe. We use this experience, combined with modern, agile ways of working and a broad, tailored product portfolio to meet all the requirements of this young industry.

Offering the perfect combination of a market-leading brake portfolio, an agile way of working, and unmatched customization flexibility we help you find the right solution for your application.

Our Heros for AGV solutions

Spring-applied brakes Servo Slim Line

Electromagnetically actuated brakes are designed to bring a moving load to a standstill and hold it or to fix the position of an inactive load. The closing or opening of the brake usually must happen in a split of a second to be able to brake loads quickly and safely in high-frequency applications.

The Servo Slim Line spring-applied brake was designed primarily for applications with hollow shafts and small installation spaces. The "slim" single-disc brakes are flatter and lighter than the market standard in relation to their power density. Their large inner diameter makes them perfect for hollow shaft drives where the cables are routed inside through the joint or for applications where only minimal installation space is available.

MORE ABOUT THE SERVO SLIM LINE

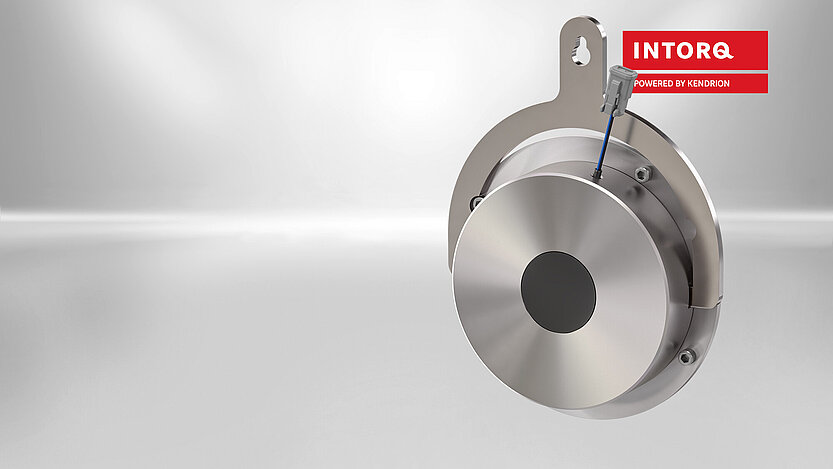

Spring-applied brakes INTORQ BFK457

These electromagnetically released spring-applied brakes can be used wherever rapid deceleration of moving masses or controlled holding of masses is required. Since the braking force comes from pressure springs, the braking torque, which is generated by friction, is available when no current is applied – even in the event of a power failure.

To safely stop and hold the loads, e.g. at a ramp, the INTORQ BFK457 is installed in the drive unit to ensure work safety during operation. Quick mounting with integrated mounting screws and fixed air gap make this spring-applied brake even more attractive.

Benefits at a glance

Guaranteed torque and service life

Variable shaft-hub connection

Front & flange mounting possible

Flexible cable routing

Fast opening and closing times

Low inertia and weight