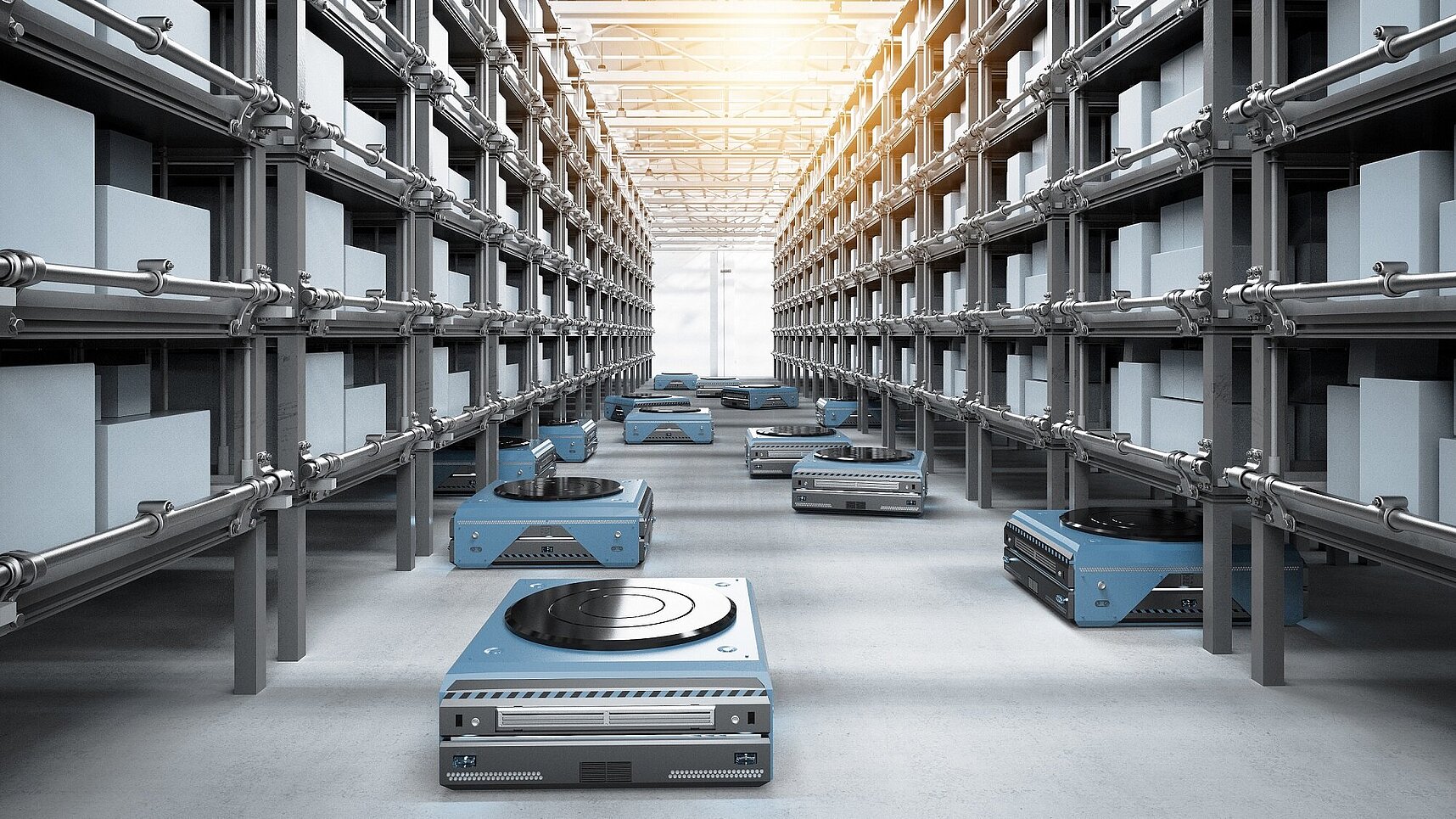

Compact design trend

In drive technology, and many other applications, there’s a clear trend towards more compact designs. The demands on electric drives are high. They must have high power density, combine various electronics, and are required to be ‘intelligent’. But the increasingly compact arrangement of components can have a negative impact on the temperature inside the application. For example, in a robot joint, many components - performance electronics, drive, transmission, sensor systems and brakes – are integrated in a small space. This requires proper heat reduction.

Compact control modules for electromagnetic brakes are a very practical and sustainable solution. They lower the holding current, reducing the required energy and consequently heat generation.

Critical temperature balance in compact installation spaces

Electromagnetic brakes that are released with residual current are ideal safety brakes when moving masses or loads need to be kept at a standstill. In case of a power failure or a failure of the energy supply, for instance because of a line breakage, the system is safely stopped, keeping humans or capital goods unharmed.

In principle, the function and properties of the safety brakes are based on simple physical relationships. If the coil is de-energized, the brake is closed. The armature is pressed against the friction disk by force of a spring or a permanent magnet, activating the braking effect. If, however, current flows through the coil, a magnetic field is created that attracts the armature disc and releases the rotor, also releasing the brake. This also means that the electromagnetic brake consumes energy, thus generating heat while there is no braking operation.

Heat generation is always a challenge when applications require power density or temperature-sensitive electronics must be integrated in the drive. The more compact the installation space, the bigger the challenge. For this reason, manufacturers it’s imperative that the drive components generate as little heat as possible.

Less heat, more power, and significantly faster switching time

Our „Slim Collection" control modules help resolve any heat generation issues in compact drives. The modules consist of a time-controlled rectifier with electronic fast shutdown and are customized for electromagnetic actuators.

The modules are available as PWM modules for servomotors and as overexcitation bridge or half-wave rectifiers for asynchronous motors. They are suitable for brakes with up to appr. 225 W holding resp. 450 W switching power.

In the initial phase, the module temporarily emits a high output voltage via a bridge rectifier in the so-called overexcitation time. This results in a fast and powerful release of the brake. Furthermore, when switched on, the full switching voltage can be temporarily provided, reducing the opening time. After that, the electronics controlled by a microcontroller switches down to a variable value. This reduction of the holding voltage by the new control modules results in an energy saving of up to 75% in normal motor operation. Accordingly, the heat balance of the complete drive is significantly eased by the innovative process of these actuators.

When the input voltage is switched off or fails, an integrated voltage sensor causes the electronic output voltage on the DC side to switch off. For this reason, the electromagnetic brake switches faster, is applied and can safely bring the application to a standstill with reduced overtravel. At the same time, high switch-off voltages generated by inductive loads are limited to acceptable values in the module.

For applications where direct current is available for the electromagnetic brake anyway, the control module is designed as a PWM module. This makes it possible to optimize the switching behavior and minimize the self-heating, thus increasing the lifetime of the robot, and reducing energy costs.

To get a clear signal with the PWM module in continuous operation, a free-wheeling diode above the electromagnetic brake is a must. When the power supply is switched off, a switch over to a varistor occurs. Compared to conventional solutions, this allows for significantly faster closing times.

Unique, innovative manufacturing technology saves installation time

Kendrion control modules boast more unique features, including their compact design. They require less space than any other solution currently available on the market. There are several reasons for this: We only use up-to-date, highly integrated microelectronic and power components, such as small surface-mounted components that can be automatically mounted. This also applies to the terminal block. In this way, we can mount all components using reflow soldering, which significantly optimizes and shortens the production process. We can also produce small batches at competitive prices.

The complete electronics of the control module is placed on a PCB which is subsequently overmolded under relatively low pressure with plastic that is temperature-resistant up to 150 °C. Thanks to the availability of highly temperature-resistant plastic, this hot-melt process, proven in plug technology, can now also be used for power electronics. The plastic ensures good heat dissipation and protects the components against vibration, shock and adversary ambient conditions. This means the “Slim Collection” modules do not require an additional housing which in turn, delivers cost efficiencies, saves space, and reduces installation time. With dimensions of just 60 x 24 x 13 mm, the small module can be easily integrated near the drive or in the terminal box of small and medium-sized motors and can be attached with just one central screw. The wires of the supply cable are connected to the respective motor terminals. The connection of the electromagnetic brake to the module is eased by the insulation displacement mechanism. The supply line of the brake can be mounted without tools; it is no longer necessary to screw it on. And finally, this innovative production technology provides a further benefit: thanks to low tooling costs, customer-specific designs can be easily produced in small quantities.

We are proud to be the first manufacturer of control modules to use this innovative, production technology. The benefits for our customers are clear: compact design, high power density, easy installation, and favorable price and energy saving up to 75%!

Do you have an application that requires combining many heat-generating components? Feel free to contact us, we’re happy to explore your perfect control module solution with you!

In our tutorial you can learn about all the benefits of the control module in simple words.